I think I have a shiny new favourite top pattern – the Odell by Notches Patterns, and the bonus is that it’s free! I had seen it on Instagram a while ago and fell in love with the sleeve, of course! I just love the possibilities to use up different colurs of the same fabric, using a print cut in different directions, and just basically having fun with that sleeve.

Odell Top

Notches patterns

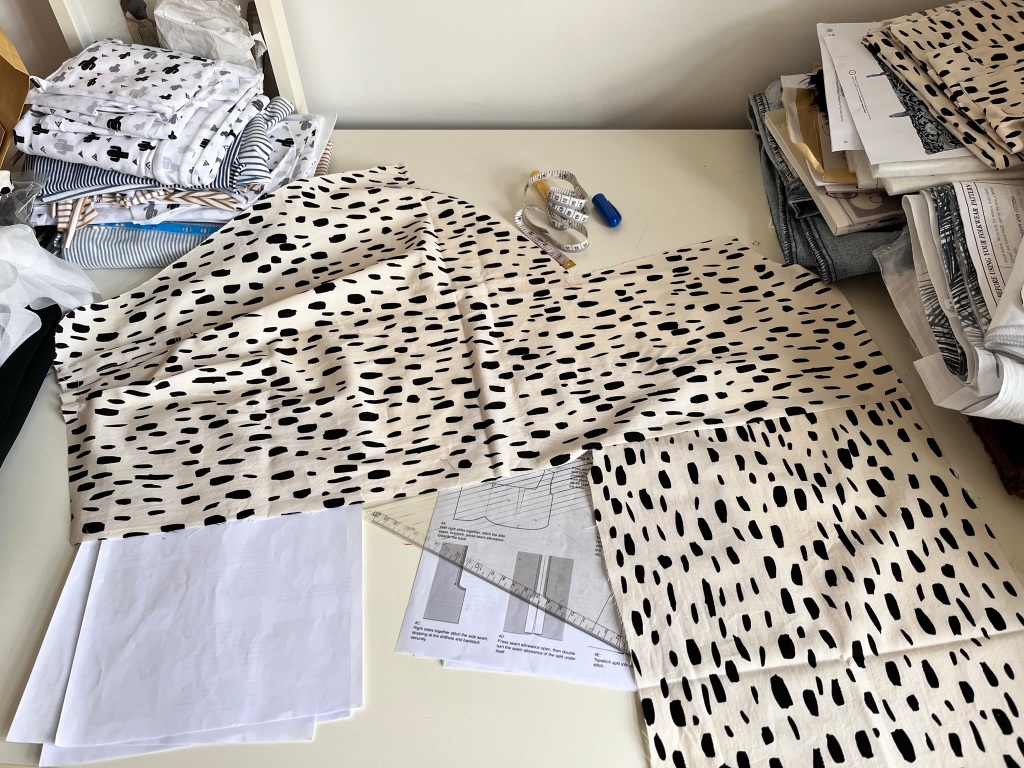

I traced the sizes 18-22, not sure whether I could get away with the smaller size and do a FBA, or just do one fo the bigger ones. I decided to start with toiling the smaller one without the FBA just to see where it was going. I was pleasantly surprised to see that the smaller one was just fine, plenty of ease. But I did need to adjust the dart, it was just too wide and pointy. I lengthened it first, about 2.5cm longer, which looks much better, and I rotated some of it out into a new temporary waist dart. It was temporary because I ignored making a dart and took half of it out in the side seam. So the blouse is less straight and a bit fuller in the front, but I’m happy with it. I also found it too long for me, so it’s been shortened by 8cm! And no – I didn’t mistakenly cut the dress length…

Last year, when Mum came to visit, she brought me two 2m length of black and white Shweshwe. I thought it would be the perfect fabric for this top, the shweshwe had good body. I only just had enough to get all the important pieces out, but I had to cut the facings from plain black lawn in the end! The curved, teardrop shapes of the sleeve pieces mean this top is a little more fabric hungry than you’d expect. If I hadn’t shortened the top, I wouldn’t have got it on at all! This is because shweshwe is only 90cm wide, so a “normal” width fabric wouldn’t have the same issues.

Construction is pretty easy, just keep an eye on which sleeve pieces are which! Each raglan balloon sleeve consists of six pieces! I assembled the sleeves before adding them to the bodice, unpinning each piece one at a time as needed. My overlocker was acting up so I just zigzagged all the seams, shweshwe is too stiff to use French seams. I think I’ll leave the facing off next time and just bias bind the neck. I like the lower back neckline, could be cute in the summer. It’s nice worn with a layer underneath, but I can’t wait to wear it in the warm weather!

Now, on to the practical stuff. I’ve worn this top once so far, which means one wash and one opportunity to iron it… The fabric irons beautifully, and like all shweshwe will soften each time its washed. My problem, if it’s a problem, is ironing the sleeves!! Some areas of the sleeves are ok to iron on the flat, but I found myself reaching for the tailor’s ham in order to iron the lower edges where the pattern pieces are more rounded to give that balloon shape. I will probably not rush to make this pattern from linen!

But I will make another, I really love that sleeve, and for now, the faff with ironing it is worth it!